MultiTech LoRaWAN Wireless Industrial Sensors

LoRaWAN® Wireless Industrial Sensors can be used for a variety of applications across numerous industries.

The wireless voltage and 4-20mA current loop sensors are typically used in applications where there is a need to monitor and measure voltage or current, such as the health of a battery, detecting a power failure, and machinery monitoring health. Continuous 24/7 monitoring of your assets will detect and alert you before a failure occurs, saving you downtime and expensive repairs. These LoRaWAN® industrial sensors are designed for outdoor/industrial use.

Current Transformer

LoRaWAN® | Model: CT300

The MultiTech CT300 is a compact, self-powered wireless current sensor that makes it easy to monitor energy usage without complex wiring or battery maintenance. Designed for fast, non-intrusive installation, it clamps directly onto existing conductors and transmits accurate current and amp-hour data over LoRaWAN®. Ideal for energy monitoring, predictive maintenance, and load analysis, the CT300 helps reduce energy waste, improve equipment performance, and support ESG goals—making it a smart, scalable solution for industrial and commercial environments.

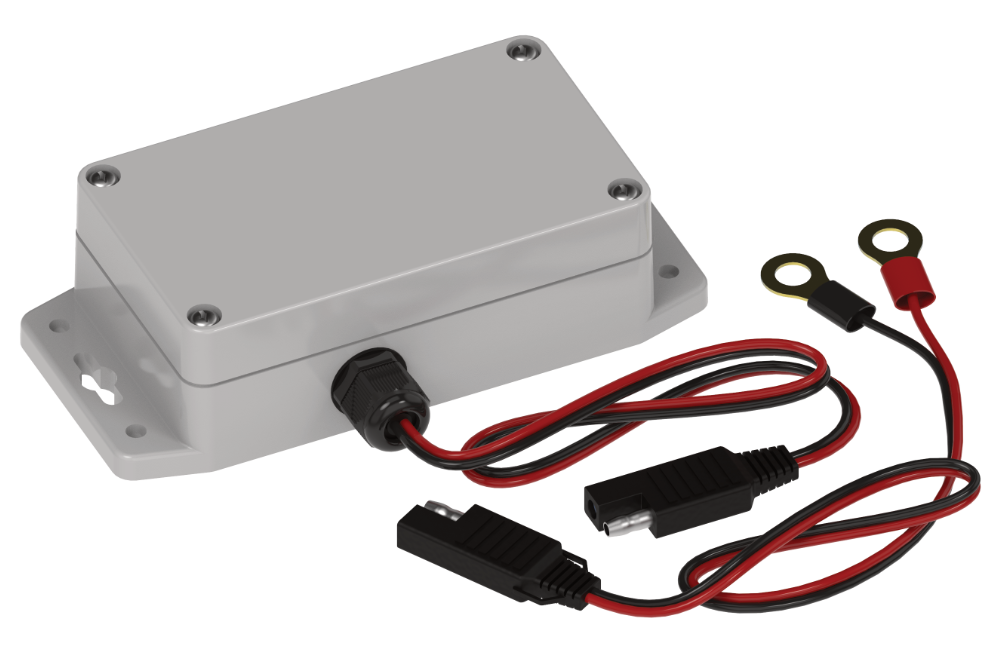

Industrial Wireless Voltage Sensors

LoRaWAN® | Model: RBS306-VM30-US

The wireless voltage sensor measures voltages between 0-30V with 10mV precision. When the voltage rises above or drops below a threshold, an alert is sent over the wireless network. An indoor/smart building version is also available for low cost applications. There are also current sensor attachments that can be added to the voltage sensor to measure AC current from a range of 0-5A up to a range of 0-300A.

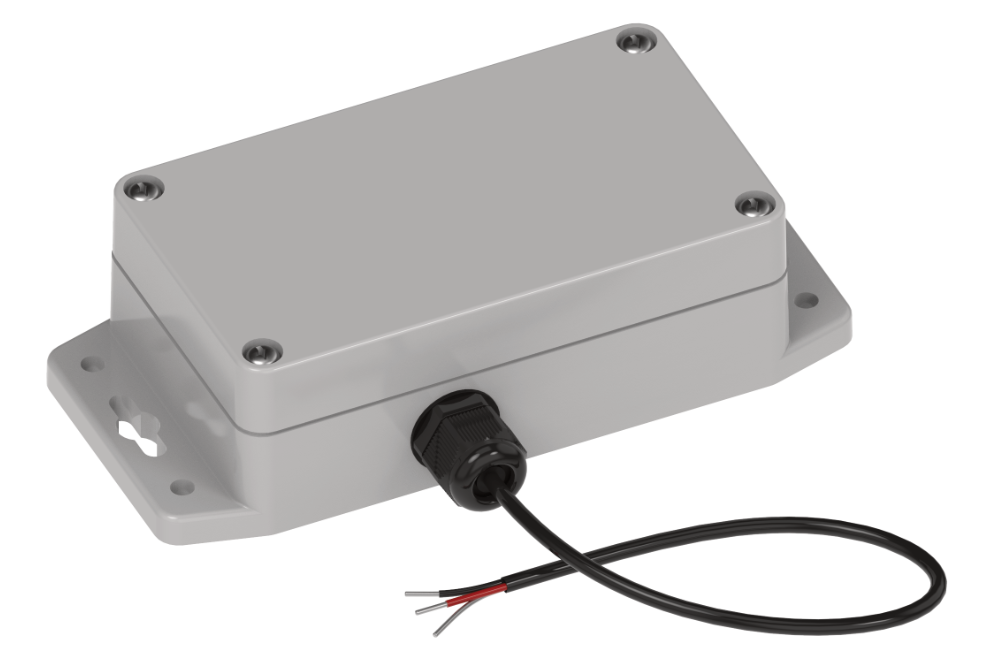

Industrial 4-20mA Current Loop Sensor/Bridge

LoRaWAN® | Model: RBS306-420MA-US

The 4-20mA Current Loop Sensor can measure the current from another device or sensor. It uses a 10-bit ADC to measure an analog value between 4 and 20mA with a 10uA resolution. If the measured value rises above or falls below the configured thresholds, an alert is sent over the wireless network. The weather-proof enclosure makes the sensor suitable for outdoor and industrial use. The 4-20mA sensor can also be used as a bridge device to enable a wide variety of sensors with only a 4-20mA output.